Advantage

1. Affordable price: Compared with some special materials or high-performance pipe fittings, ordinary pipe fittings have obvious advantages in purchase cost, which can save money for projects or daily use.

2. Economical and practical: For general fluid transportation or connection needs, ordinary pipe fittings can meet basic functions at a lower cost and are cost-effective.

3. Widely applicable: The specifications and models of ordinary pipe fittings are relatively common and can be adapted to a variety of different pipeline systems and application scenarios, making it easy to connect with different pipe materials.

4. Easy to install: Due to its versatility, installers are more familiar with ordinary pipe fittings, and the installation process is relatively simple and fast, reducing construction difficulty and time.

Product Introduction

Ordinary pipe fittings are a general term for components used in pipeline systems for connection, control, direction change, diversion, sealing, support, etc. Common ordinary pipe fittings include elbows, tees, crosses, reducers, etc. Pipe fittings are used in disciplines such as water conservancy technology, irrigation and drainage.

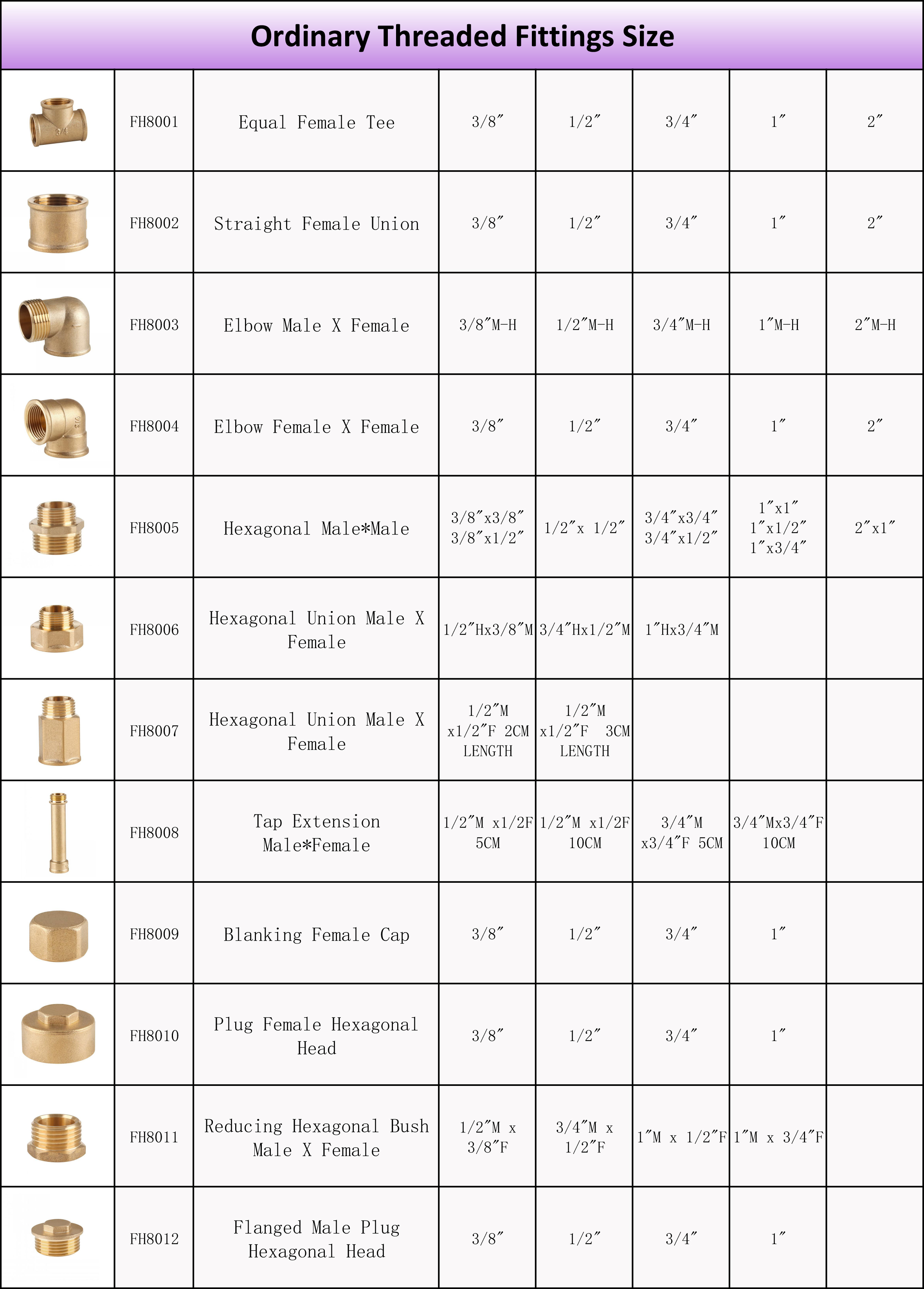

According to the connection method, it can be divided into four categories: socket pipe fittings, threaded pipe fittings, flange pipe fittings and welded pipe fittings. There are elbows (elbows), flanges, tees, four-way pipes (cross heads) and reducers (large and small heads), etc. Elbows are used where pipes turn to change the direction of the pipes, and can be divided into different angles such as 90-degree elbows and 45-degree elbows; flanges are used to connect pipes to each other and are connected to the pipe ends; tees are used to A pipe can be divided into two branch pipes; a four-way can be used to divide a pipe into three branch pipes; a reducer is used where two pipes of different diameters are connected.

Pipe fittings can be classified according to manufacturing standards into national standards, electrical standards, ship standards, chemical standards, water standards, American standards, German standards, Japanese standards, Russian standards, etc. According to the production method, it can be divided into pushing, pressing, forging, casting, etc. Ordinary pipe fittings are usually made of metal, plastic and other materials. When selecting ordinary pipe fittings, factors such as the material of the pipe, working pressure, temperature, medium, etc. need to be considered to ensure the matching and reliability of the pipe fittings and the pipeline system.