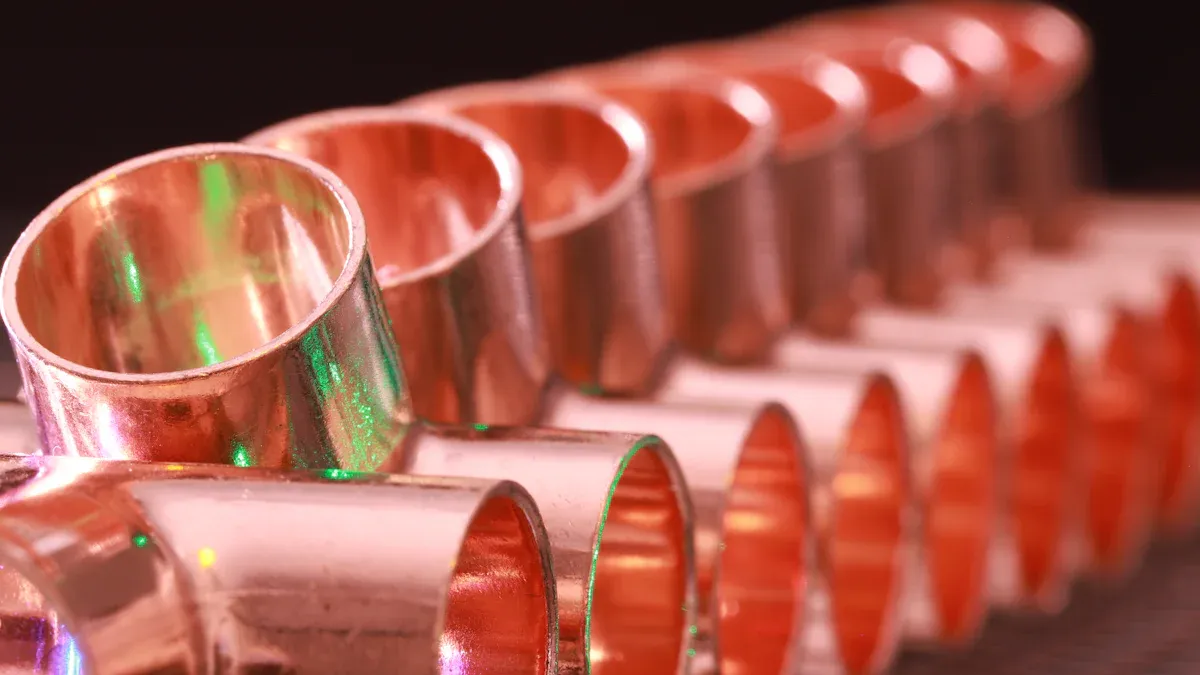

I use push fittings when I need a fast, secure way to join pipes. These connectors stand out from traditional fittings because I can install them without tools.

- Their main purpose: simplify plumbing by enabling secure, leak-free joints in seconds.

The growing popularity of pushing fittings highlights their efficiency and safety in modern pipework.

Key Takeaways

- Push fittings allow quick, tool-free pipe connections with a secure, leak-free seal, saving time and effort during installation.

- The push-to-connect design uses metal teeth and an O-ring to hold pipes firmly and prevent leaks, making maintenance and repairs easier.

- Push fittings work well in homes and businesses for water, heating, and air systems, offering flexibility and reliability compared to traditional fittings.

How Push Fittings Work

Push-to-Connect Mechanism

When I use push fittings, I rely on a simple yet effective push-to-connect mechanism. This design allows me to join pipes by pushing them directly into the fitting. Inside each fitting, a set of metal teeth grips the pipe, while a rubber O-ring forms a watertight seal. I do not need any tools or adhesives, which makes the process quick and straightforward.

Tip: I always check the pipe ends for smoothness before connecting. Any rough edges can affect the seal and grip.

In industrial settings, I have seen push fittings last between 12 and 18 months under high pressure. Their lifespan depends on the material, operating conditions, and environmental factors. I look for signs such as deformation, cracks, or leaks to assess their condition. Regular inspections and leak tests help me maintain system reliability and prevent unexpected failures.

- I monitor for:

- Deformation or visible cracks

- Discolouration

- Unexpected disconnections

- Leaks at the joint

To ensure long-term performance, I follow manufacturer guidelines and replace fittings proactively when I notice wear or after a set period.

Step-by-Step Installation Process

I find the installation process for push fittings remarkably straightforward. Here is how I typically complete the connection:

- I cut the pipe to the required length, ensuring the end is square and smooth.

- I remove any burrs or sharp edges from the pipe end.

- I mark the insertion depth on the pipe using the fitting’s guide.

- I push the pipe firmly into the fitting until it reaches the marked depth.

- I tug gently on the pipe to confirm a secure connection.

This process saves me significant time compared to traditional fittings, which often require wrenches, soldering, or adhesives. I can also disconnect the pipe easily if I need to make adjustments or repairs. The push-to-connect mechanism has proven reliable in both domestic and commercial applications, as confirmed by statistical assessments such as Failure Mode and Effects Analysis (FMEA) and reliability growth testing. These methods help me identify potential risks and validate the robustness of the fittings under various conditions.

Achieving a Secure Seal

A secure seal is essential for leak-free performance. When I insert the pipe, the O-ring inside the fitting compresses around it, creating a tight barrier against water or gas. The metal teeth hold the pipe in place, preventing accidental disconnection.

Controlled experiments have shown that push fittings maintain their seal integrity even under significant pressure. In these tests, researchers monitor pressure inside a sealed vessel to measure how well the fitting resists leaks. They record maximum and average pressures, which indicate the strength of the seal. Pressure versus time plots reveal how the seal responds to increasing loads, and repeated tests confirm the reliability of the connection.

Comparative laboratory tests also highlight the advantages of push fittings over traditional threaded or welded connections. Threaded fittings often begin leaking at lower stress levels, while push fittings maintain their seal for longer. This performance gives me confidence when I choose push fittings for critical applications.

Push Fittings Features, Applications, and Comparison

Key Features of Push Fittings

When I assess push fittings, I look for features that make installation and maintenance easier. Surveys often use rating scales, such as 1 to 5, to measure satisfaction with these features. Most users rate ease of use and speed of installation highly. The push-to-connect mechanism, tool-free assembly, and reliable sealing stand out as top-rated aspects. Many respondents also value the ability to disconnect and reuse fittings, which adds flexibility to plumbing projects.

Common Applications in Domestic and Commercial Settings

I see push fittings used widely in both homes and businesses. Their versatility makes them suitable for water supply, heating systems, and compressed air lines. According to recent industry reports, household use accounts for about 60% of the market, making it the dominant segment. Commercial applications, such as office buildings and hotels, represent around 30% and are growing rapidly. Industrial use holds a smaller share at 10%, but I notice increasing adoption in specialised environments.

| Application Sector | Market Share (2023) | Growth Trend |

|---|---|---|

| Household Use | ~60% | Dominant segment |

| Commercial Use | ~30% | Fastest-growing segment |

| Industrial Use | ~10% | Smaller share |

Advantages of Push Fittings

I have found several advantages when using push fittings:

- Quick installation saves time and reduces labour costs.

- No need for special tools or advanced skills.

- Reliable sealing with O-rings prevents leaks.

- Easy disconnection allows for repairs or changes.

- Suitable for various pipe materials, including plastic and metal.

Industry studies show that push-fit technology can reduce installation time by up to 40% and labour by as much as 90%. These improvements lead to lower costs and higher productivity.

Disadvantages and Limitations

I always consider the application environment before choosing fittings. While push fittings offer many benefits, I check compatibility with system pressure and temperature requirements. I also monitor O-ring condition during maintenance to ensure long-term performance.

Push Fittings vs Traditional Fittings

When I compare push fittings to traditional options, I notice clear differences:

| Feature / Aspect | Push-To-Connect Fittings | Compression Fittings |

|---|---|---|

| Installation Time | Quick, tool-free, ideal for frequent changes | Longer, requires tools and expertise |

| Pressure Tolerance | Lower, not for extreme conditions | High, suitable for demanding systems |

| Cost | Higher upfront cost | More cost-effective per unit |

| Reusability | Reusable, easy to disconnect | Nonreusable, ferrules deform |

| Maintenance | O-ring may need checking | Maintenance-free once installed |

| Application Suitability | Best for water, air, frequent adjustments | Best for permanent, high-pressure installations |

| Tool Requirements | None | Specialised tools needed |

I choose push fittings when I need speed, flexibility, and ease of use, especially in domestic and commercial settings.

I rely on push fittings for quick, reliable pipe connections in both domestic and commercial projects. These fittings save time, reduce labour, and offer secure seals. I recommend push fittings when I need fast installation, flexibility, and minimal disruption to existing systems.

- Main uses: water supply, heating, compressed air

- Key benefit: tool-free, leak-free connections

FAQ

How do I know if a push fitting is properly connected?

I listen for a click and feel resistance when the pipe seats. I always check the fitting by gently pulling to confirm a secure connection.

Can I reuse push fittings after disconnection?

Yes, I can reuse most push fittings. I inspect the O-ring and fitting for damage before reinstalling to ensure a reliable seal.

What types of pipes work with push fittings?

I use push fittings with copper, PEX, and some plastic pipes. I always check the manufacturer’s guidelines for compatibility with specific pipe materials.

Post time: Jun-23-2025