Ordinary threaded pipe fittings connect pipes in plumbing systems through screw threads. I often see them used in residential plumbing, industrial pipelines, and mechanical systems. These fittings ensure secure and leak-proof connections, which are critical for maintaining the integrity of fluid transport systems. Their versatility makes them indispensable in various applications.

Key Takeaways

- Threaded pipe fittings help make strong, leak-free connections in plumbing.

- Picking the right fitting means checking material, pressure, and temperature needs.

- Materials like stainless steel or brass resist rust and last longer in use.

Types of Ordinary Threaded Pipe Fittings

Ordinary threaded pipe fittings come in various types, each designed to serve specific purposes in plumbing and industrial systems. Below, I’ll explore the most common types and their applications.

Elbows

Elbows are essential for changing the direction of a pipe. These fittings come in different angles, such as 45° and 90°, to suit various system layouts. For example, a 90° elbow redirects flow sharply, while a 45° elbow provides a gentler transition. These fittings are widely used in residential plumbing and industrial piping to optimize space and ensure smooth fluid flow.

Tip: When selecting elbows, consider the material compatibility with your piping system to prevent corrosion or wear over time.

Tees

Tees are shaped like the letter “T” and feature three outlets. They allow a single pipe to branch into two separate lines, making them ideal for distributing fluids or gases. For instance, tees are commonly used in HVAC systems to split airflow or in water distribution networks to direct water to multiple locations.

Couplings

Couplings connect two pipes together, ensuring a secure and leak-proof joint. These fittings are available in various materials, including stainless steel and carbon steel, to match different application requirements. Hydraulic pressure testing has shown that high-quality couplings maintain zero leakage under extreme conditions, making them reliable for high-pressure systems.

Caps and Plugs

Caps and plugs are used to seal the ends of pipes. Caps fit over the pipe’s exterior, while plugs are inserted into the pipe’s interior. These fittings are crucial for temporarily or permanently closing off unused pipe sections, preventing leaks or contamination.

Reducers

Reducers connect pipes of different diameters, ensuring a smooth transition between them. They come in two main types: concentric reducers, which align the centerlines of the pipes, and eccentric reducers, which offset the centerlines. Properly installed reducers minimize turbulence and pressure drops, enhancing system efficiency in industries like oil and gas, water treatment, and HVAC.

- Key Benefits of Reducers:

- Improve fluid flow by reducing turbulence.

- Optimize energy efficiency in HVAC systems.

Flanges

Flanges are flat, circular fittings used to connect pipes, valves, or other equipment. They are bolted together and sealed with gaskets to create a tight joint. Flanges are particularly effective in high-pressure environments, such as subsea oil pipelines, where durability and leak resistance are critical. Materials like duplex stainless steel and alloy steel ensure these fittings withstand extreme conditions.

| Material Type | Application Context | Key Features |

|---|---|---|

| Duplex Stainless Steel | Subsea Oil Pipelines | Excellent resistance to corrosion and stress cracking. |

| Alloy Steel (SA-182 F316L) | High-Pressure Environments | High strength and toughness for extreme pressures. |

Crosses (Four-Way Fittings)

Crosses, also known as four-way fittings, have four outlets arranged in a cross shape. These fittings are used to divide a single pipe into three branches, making them useful in complex piping systems. For example, crosses are often employed in fire protection systems to distribute water to multiple sprinkler lines.

Note: Crosses should be installed carefully to avoid stress concentration, which can weaken the piping system over time.

By understanding the unique features and applications of these fittings, you can select the right type for your specific needs. Ordinary threaded pipe fittings play a vital role in ensuring the efficiency and reliability of plumbing and industrial systems.

Applications of Threaded Pipe Fittings

Threaded pipe fittings are versatile components that find applications across various industries. Their ease of installation, cost-effectiveness, and adaptability make them indispensable in many systems. Below, I’ll explore their use in key areas.

Residential Plumbing Systems

In residential plumbing, threaded pipe fittings play a crucial role in water and gas distribution. I often see them used in connecting pipes for kitchens, bathrooms, and outdoor water systems. Their ability to create leak-proof joints ensures the safety and efficiency of household plumbing. For example, couplings and elbows are commonly used to extend pipelines or change their direction in tight spaces.

Tip: Always choose fittings made from corrosion-resistant materials like stainless steel or brass for long-lasting performance in residential systems.

Industrial Piping Systems

Industrial facilities rely heavily on threaded pipe fittings for transporting fluids, chemicals, and gases. These fittings are particularly useful in moderate-pressure environments where flexibility and maintenance are essential. I’ve observed their widespread use in manufacturing plants, where reducers and tees help manage complex piping networks.

| Application Type | Description |

|---|---|

| Plumbing Systems | Extensively used in residential & commercial plumbing for water and gas pipelines. |

| Industrial Manufacturing Systems | Used in manufacturing plants for chemical or fluid transport systems under moderate pressure. |

The ability to disassemble and reuse these fittings adds to their cost-effectiveness, especially in dynamic industrial settings.

HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems depend on threaded pipe fittings for secure and flexible connections. These fittings simplify the installation of ductwork and piping, ensuring efficient airflow and temperature control. I’ve noticed that flanges and tees are particularly popular in HVAC systems, as they allow for easy modifications and repairs.

Note: Properly installed threaded fittings in HVAC systems can significantly reduce energy loss and improve overall system efficiency.

Oil and Gas Pipelines

Threaded pipe fittings are essential in oil and gas pipelines, especially in low-pressure sections. They connect pipes securely while adhering to strict safety and environmental standards. For instance, Alberta’s oil and gas industry follows regulations like CSA Z662 and API 5L to ensure pipeline integrity.

- Key compliance standards include:

- CSA Z662 for pipeline design and maintenance.

- API 5L for seamless and welded steel pipes.

- ASME B31.3 for process piping systems in refineries.

These fittings also offer reusability, contributing to cost savings and sustainability in the oil and gas sector.

Fire Protection Systems

In fire protection systems, threaded pipe fittings are indispensable for connecting sprinkler lines and other components. Their ability to accommodate modifications and repairs makes them a preferred choice in this field. Studies show that threaded fittings perform reliably under seismic conditions, with minimal leakage even at high drift ratios.

| Findings | Details |

|---|---|

| Leakage Performance | No leakage in welded assemblies at a drift ratio of 4.3%; minor leaks in threaded piping at 2.2%. |

| Seismic Study Insights | Focused on threaded tee joints, revealing rotational capacities and fragility characteristics. |

This reliability ensures that fire protection systems remain operational during emergencies, safeguarding lives and property.

Industrial Cooling Water Systems

Threaded pipe fittings are widely used in industrial cooling water systems to manage the flow of water in heat exchangers and cooling towers. Their ability to handle moderate pressure and temperature variations makes them ideal for this application. I’ve seen reducers and crosses used extensively to optimize water distribution and maintain system efficiency.

The flexibility of these fittings allows for easy maintenance and upgrades, ensuring uninterrupted operation in critical cooling processes.

By understanding the diverse applications of threaded pipe fittings, I can appreciate their importance in ensuring the efficiency and reliability of various systems. Their adaptability and performance make them a cornerstone of modern infrastructure.

Advantages and Disadvantages of Threaded Pipe Fittings

Advantages

Threaded pipe fittings offer several benefits that make them a popular choice in plumbing and industrial systems. First, their ease of installation stands out. I’ve found that these fittings require no specialized tools or welding, which simplifies assembly and reduces labor costs. This feature makes them ideal for projects where time and budget constraints are critical.

Another advantage is their reusability. Unlike welded connections, threaded fittings can be disassembled and reused without damaging the pipes. This flexibility proves invaluable in systems that require frequent modifications or maintenance. For example, in industrial cooling water systems, I’ve seen threaded fittings reused multiple times during system upgrades, saving both time and resources.

Threaded fittings also excel in moderate-pressure applications. Their ability to create secure, leak-proof connections ensures reliability in residential plumbing, HVAC systems, and other environments where extreme pressures are not a concern. Additionally, their availability in various materials, such as stainless steel and brass, allows for compatibility with different piping systems.

Tip: Always select fittings made from corrosion-resistant materials to enhance durability and performance.

Disadvantages

Despite their advantages, threaded pipe fittings have limitations that must be considered. Controlled testing and statistical evaluations have identified several drawbacks, as shown in the table below:

| Disadvantage | Description |

|---|---|

| Vulnerability to fatigue damages | Threaded fittings should not be used for hazardous materials due to this risk. |

| Leakage due to rapid temperature and pressure changes | Sudden changes can compromise the integrity of the fittings. |

| Prone to port expansion or cracking from over-tightening | Over-tightening can lead to structural failures. |

| Difficulty in orienting other fittings for joining | This can complicate installation and maintenance. |

| Contamination from lubricants used in sealing | Lubricants can contaminate the piping system, posing risks. |

| Unsuitable for high-pressure applications | Threaded fittings are not recommended for high-pressure systems. |

| Not recommended in corrosive and erosive environments or cyclic loading | ASME B31.3 advises against their use in these conditions. |

These disadvantages highlight the importance of selecting the right fitting for the application. For instance, I avoid using threaded fittings in high-pressure or corrosive environments, as their performance may not meet safety standards. Proper installation techniques, such as avoiding over-tightening, can also mitigate some of these issues.

By understanding both the strengths and weaknesses of ordinary threaded pipe fittings, I can make informed decisions that ensure system efficiency and safety.

How to Select the Right Threaded Pipe Fitting

Choosing the right threaded pipe fitting requires careful consideration of several factors. Each decision impacts the system’s performance, durability, and safety. Below, I’ll guide you through the key aspects to evaluate.

Consider Pipe Material Compatibility

The material of the fitting must align with the pipe and the fluid it will carry. For example, stainless steel resists corrosion in water systems, while brass performs well in moderate-temperature applications. I always recommend selecting materials that resist degradation caused by environmental factors like humidity or chemical exposure.

Tip: Use fittings made from malleable cast iron for general plumbing, as they meet standards like BS EN 10242 and ISO 49:1994 for durability and performance.

Evaluate Pressure and Temperature Requirements

Threaded fittings must withstand the system’s maximum pressure and temperature. For demanding conditions, I rely on performance data to ensure safety and efficiency.

| Standard | Description |

|---|---|

| BS EN 10242 | Design and performance requirements for malleable cast iron. |

| ISO 49:1994 | International standard for pressure/temperature ratings. |

For example, brass fittings handle temperatures up to 80°C, while steam applications may require fittings rated for 10 bar at 180°C. Always consult P-T charts to adjust pressure ratings for temperature changes.

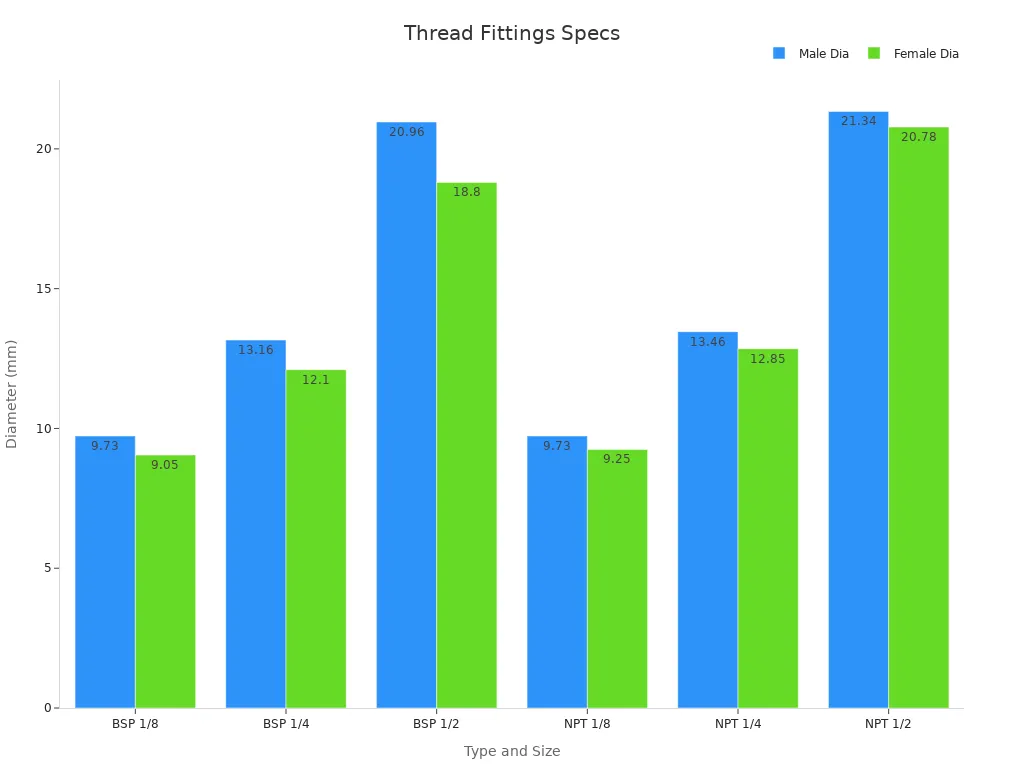

Choose the Correct Thread Type and Size

Thread type and size are critical for secure connections. NPT threads, with their tapered design, ensure pressure-tight sealing. Sizing charts help match fittings to pipe dimensions, avoiding leaks or misalignment.

| Thread Type | Size | Male Diameter (mm) | Female Diameter (mm) |

|---|---|---|---|

| BSP | 1/8″ | 9.73 mm | 9.05 mm |

| BSP | 1/4″ | 13.16 mm | 12.1 mm |

| NPT | 1/8″ | 9.73 mm | 9.25 mm |

| NPT | 1/4″ | 13.46 mm | 12.85 mm |

Note: BSP threads have a 55° angle, while NPT threads feature a 60° taper. Choose based on your system’s requirements.

Assess the Application Environment (e.g., Indoor vs. Outdoor)

Environmental factors like temperature fluctuations, UV exposure, and humidity influence fitting performance. For outdoor systems, I prefer corrosion-resistant materials like galvanized steel or stainless steel. Indoor systems often allow for more material flexibility, such as using brass or PVC.

By evaluating these factors, you can select threaded pipe fittings that ensure reliability, safety, and efficiency in your system.

Ordinary threaded pipe fittings serve as essential components in plumbing and industrial systems. Their versatility and reliability make them indispensable across various applications, from residential plumbing to oil pipelines. I always recommend evaluating your system’s specific requirements before selecting fittings. This ensures optimal performance, safety, and durability in every project.

FAQ

What are the most common materials used for threaded pipe fittings?

Threaded pipe fittings are commonly made from stainless steel, brass, carbon steel, and malleable cast iron. Each material suits specific applications based on durability and compatibility.

Can threaded pipe fittings handle high-pressure systems?

Threaded fittings work best in moderate-pressure systems. For high-pressure applications, I recommend using welded or flanged connections for enhanced safety and reliability.

How do I prevent leaks in threaded pipe fittings?

I always use thread sealants like Teflon tape or pipe dope. These sealants fill gaps between threads, ensuring a tight, leak-proof connection.

Tip: Avoid over-tightening fittings to prevent thread damage or cracking.

Post time: Jun-04-2025