Discover the leading Brass Fittings Manufacturers. These companies are renowned for their superior products in demanding industrial applications. This comprehensive guide highlights various top-tier companies. It details their specific specialties and what truly sets them apart in today’s competitive market.

Key Takeaways

- Top brass fitting makers like Parker Hannifin and Swagelok offer many products. They meet different industrial needs.

- Brass fittings are strong and resist rust. They work well in tough places like factories and oil rigs.

- Choosing the right maker means looking at their products, quality checks, and customer help. This ensures good performance.

Parker Hannifin: A Leading Brass Fittings Manufacturer

Establishment and Core Offerings

Parker Hannifin stands as a prominent entity among Brass Fittings Manufacturers. Arthur L. Parker established the firm as the Parker Appliance Company in Ohio around 1917 or 1918. The company faced a setback in 1919 but restarted in 1924. The name officially changed to Parker Hannifin in 1957 after acquiring Hannifin. Today, Parker Hannifin offers a comprehensive range of brass fittings. Their primary product lines include:

- Pipe Fittings and Port Adapters

- Adaptors, Plugs, and Manifolds

- Brass 45° Flare Fittings

- Brass Compression Fittings, Compress-Align

- Inch Brass Compression Fittings

- Brass Hose Barb Fittings

These offerings cater to diverse industrial needs, providing reliable connections for various fluid and pneumatic systems.

Industrial Applications and Innovations

Parker Hannifin’s brass fittings serve numerous critical industrial applications. These include:

- Pneumatics

- Cooling

- Automotive Process

- Lubrication

- Fluid Transmission

- Packaging

- Industrial Machinery

- Pneumatic Machinery Equipment at Medium and High Pressure

- Lubrication Systems

- Cooling Systems

- Welding Robots

- Vacuum Applications

Parker Hannifin specifically designs its brass fittings to meet the requirements of the automotive and robotics industries. This ensures optimal adaptation and reliable operation in these demanding sectors. The company consistently innovates, providing solutions that enhance system efficiency and longevity across various industrial environments.

Swagelok: Precision Brass Fittings for Critical Systems

Company History and Product Range

Swagelok has established itself as a global leader in fluid system components. Fred A. Lennon founded the company in 1947. From its inception, Swagelok focused on delivering high-quality, reliable solutions. They are among the most respected Brass Fittings Manufacturers. Swagelok offers an extensive range of brass fittings designed for various industrial applications. Their product portfolio includes tube fittings, pipe fittings, and quick connects. These components ensure leak-tight connections in demanding environments. Specific examples of their precision brass fittings include the Brass Swagelok Tube Fitting, Union, 1/2 in. Tube OD (Part #: B-810-6) and the Brass Swagelok Tube Fitting, Union, 15 mm Tube OD (Part #: B-15M0-6). These fittings demonstrate Swagelok’s commitment to precise engineering and material quality.

Quality Standards and Key Industries

Swagelok maintains rigorous quality standards for all its products. They implement strict manufacturing processes and conduct extensive testing. This ensures every brass fitting meets high performance and reliability benchmarks. The company’s dedication to quality makes its fittings suitable for critical systems. Key industries heavily rely on Swagelok’s precision brass fittings. These sectors include:

- Oil and Gas

- Chemical Processing

- Semiconductor Manufacturing

- Power Generation

- Biotechnology

- Research and Development

Swagelok’s components perform exceptionally well in these demanding environments. They provide safe and efficient fluid handling solutions. Their brass fittings contribute to the integrity and operational efficiency of complex industrial systems worldwide.

Eaton: Diversified Brass Fittings Solutions

Overview and Product Portfolio

Eaton stands as a global power management company, also recognized among leading Brass Fittings Manufacturers. The company offers a diverse array of brass fittings solutions for various industrial needs. Eaton’s commitment to comprehensive product offerings is evident in its extensive ‘Brass Products Master Catalog’, which spans 166 pages. This catalog details a wide range of brass products. Distributors like Mid-State Sales further highlight Eaton’s broad portfolio. They list numerous brass fittings, including pipe fittings, inverted flare fittings, D.O.T. Air Brake fittings, and Push-To-Connect fittings. The selection also features SAE 45 Degree Flare fittings, ball valves, hose barbs, and ferrules. This extensive product line ensures Eaton provides suitable connection solutions for many applications.

Applications in Heavy Industry

Eaton’s brass fittings find critical applications across various heavy industries. These industries demand robust and reliable components for their fluid power systems. Eaton specifically designs its brass fittings to withstand harsh operating conditions, including high pressures and temperatures. They ensure secure and leak-free connections in demanding environments. For instance, manufacturers use Eaton’s brass fittings in heavy machinery, construction equipment, and agricultural vehicles. These components are essential for hydraulic and pneumatic systems. They facilitate the efficient transfer of fluids and gases. Eaton’s focus on durability and performance makes its brass fittings a preferred choice for maintaining operational integrity in challenging industrial settings.

Brennan Industries: Specialized Brass Fittings Manufacturer

Company Profile and Product Focus

Brennan Industries distinguishes itself among Brass Fittings Manufacturers through its specialized focus on fluid power components. The company commits to delivering high-quality solutions for various industrial applications. Brennan Industries provides a comprehensive range of brass fittings. These include general Brass Fittings, Single Ferrule Tube Fittings – Brass, and Double Ferrule Tube Fittings – Brass. Beyond these, their extensive product line encompasses other critical components. These include Tube Fittings and Adapters, O-Ring Face Seal Fittings, Flange Fittings, Conversion Adapters, and Clamps. This broad and specialized offering allows Brennan Industries to address diverse and complex industrial connection requirements effectively.

Industrial Use Cases and Advantages

Brennan Industries’ brass fittings find extensive use across numerous industrial sectors. They provide reliable and secure connections in hydraulic, pneumatic, and instrumentation systems. These fittings offer exceptional malleability, providing greater flexibility than steel while maintaining robust durability. Their extreme versatility is another key advantage. This allows for a wide array of shapes, sizes, and styles, making them suitable for diverse system requirements. Brennan’s brass fittings also exhibit high corrosion resistance. This makes them ideal for environments containing corrosive chemicals, water, slurries, and atmospheric exposure. They demonstrate high durability, performing excellently for supply lines that transport chemicals, gases, and slurries. Furthermore, these fittings possess high-temperature resistance due to their effective thermal conductivity. They can withstand higher temperatures than many other materials, though pressure ranges remain temperature-dependent. These inherent advantages position Brennan’s brass fittings as a robust and reliable choice for demanding industrial settings.

SSP Fittings Corp.: High-Performance Brass Fittings

Background and Product Specialization

SSP Fittings Corp. has established itself as a key player among Brass Fittings Manufacturers, specializing in high-performance fluid system components. The company focuses on delivering precision-engineered fittings for demanding industrial environments. SSP offers a comprehensive range of products, including various types of brass fittings designed for reliability and durability. Their product specialization extends to instrumentation fittings, valves, and tubing, ensuring secure and leak-tight connections across diverse applications. SSP’s commitment to quality materials and meticulous manufacturing processes underpins its reputation in the industry.

Critical Applications and Quality Assurance

SSP Fittings Corp.’s brass fittings find critical applications in numerous industrial sectors, including chemical processing, oil and gas, and power generation. These industries require components that perform flawlessly under extreme conditions. SSP ensures the highest quality through stringent processes. The company has been ISO 9001 Certified since 1997. They implement Kaizen methodology and Six Sigma tools. These practices ensure continuous improvement and responsiveness to customer requirements, particularly for installers of instrumentation systems. Their facility also holds ISO 9001:2000 certification. SSP operates a vertically integrated facility in Twinsburg, Ohio. This facility encompasses engineering design, machining, forging, treating, assembly, and testing all under one roof. This integrated approach allows for stringent control over materials and manufacturing processes. It ensures high-quality products and timely delivery of both standard and custom items. Since brass is one of the materials they use for fittings and filters, these quality assurance processes directly apply to their brass fittings.

Ham-Let: Advanced Brass Fittings Technology

Company Evolution and Product Innovations

Ham-Let has evolved into a significant global provider of advanced fluid system components. The company consistently focuses on innovation, developing cutting-edge solutions for various industries. Ham-Let designs and manufactures a wide array of brass fittings. These products feature advanced technology, ensuring high performance and reliability. Their commitment to research and development allows them to offer fittings that meet stringent industrial demands. Ham-Let’s product innovations often involve enhanced sealing mechanisms and improved material compositions. These advancements contribute to the longevity and efficiency of fluid systems.

Industrial Sectors Served

Ham-Let’s advanced brass fittings serve a broad spectrum of industrial sectors. The company is a strong competitor among Brass Fittings Manufacturers in the instrumentation fittings market. Their products find application in diverse environments. The Brass Compression Pipe Fitting market segments for product application include:

- Industrial

- Residential

- Commercial

- Others

Industrial brass fittings from Ham-Let handle demanding applications within factories and plants. They also see use in specialized applications. These include the HVAC and automotive industries. Their versatility and durability are crucial for efficient fluid transfer in these sectors. Ham-Let’s solutions ensure reliable connections across these varied and critical industrial settings.

Hy-Lok Corporation: Global Brass Fittings Manufacturer

International Presence and Product Lines

Hy-Lok Corporation stands as a prominent global Brass Fittings Manufacturers. The company delivers brass valves and fittings worldwide. Hy-Lok maintains its headquarters in Texas, USA, strategically positioning itself for international reach. It operates globally, with a strong presence across North America, Europe, Africa, and Asia. This extensive network ensures broad availability of their high-quality products. For instance, Hy-Lok UK, through TIS Hydraulics, serves as the master distributor for instrumentation valves and fittings in the UK. Similarly, Hy-Lok USA supplies a comprehensive range of instrumentation tube fittings and valves, including those meticulously crafted from brass. In Texas, SWPC Fluid Solutions acts as an exclusive Hy-Lok distributor. They offer the entire Hy-Lok product line, which consistently includes reliable brass fittings for various applications.

Performance in Demanding Environments

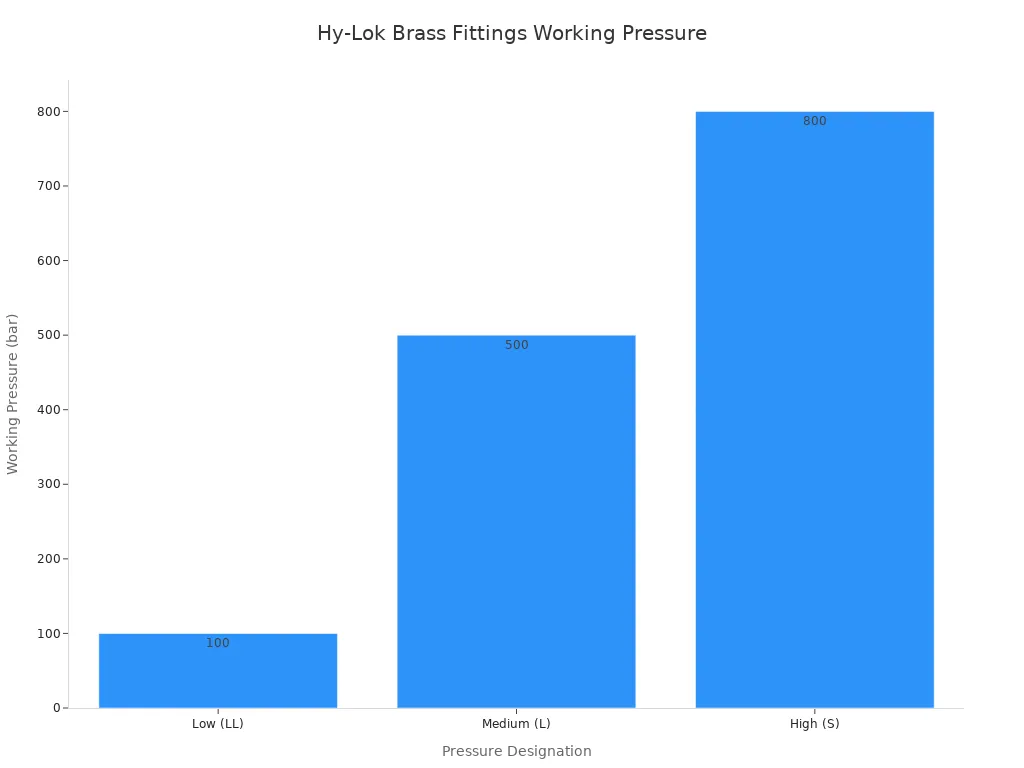

Hy-Lok brass fittings demonstrate exceptional performance in demanding industrial environments. Their robust design ensures reliability under challenging conditions. For example, Hy-Lok brass ball valves handle impressive pressure ratings up to 10,000 psi and withstand temperatures up to 500°F. Brass plug valves offer a substantial pressure rating up to 3000 psig (206 bar) at 70°F (21°C). These plug valves also feature a wide temperature rating from -10°F to 400°F (-23°C to 204°C) when equipped with a PTFE coated Viton Seal. Hy-Lok brass fittings are specifically designed for various pressure designations, ensuring suitability across diverse industrial needs:

| Material | Temperature Range | Pressure Designation | Working Pressure (bar) |

|---|---|---|---|

| Brass | -60°C to +175°C | Low (LL) | Up to 100 |

| Brass | -60°C to +175°C | Medium (L) | Up to 500 |

| Brass | -60°C to +175°C | High (S) | Up to 800 |

This robust performance makes Hy-Lok brass fittings a reliable choice for critical applications requiring durability and precision under extreme conditions.

Stauff: Robust Brass Fittings for Fluid Power

Company Heritage and Product Strength

Stauff has a long-standing reputation in the fluid power industry. The company consistently delivers high-quality components. Stauff specializes in hydraulic accessories and fluid power solutions. Their product range includes robust brass fittings. These fittings demonstrate exceptional durability and precision engineering. Stauff designs its brass fittings to withstand demanding industrial environments. The company emphasizes material quality and manufacturing excellence. This commitment ensures reliable performance and extended service life for all its products. Stauff’s heritage reflects a dedication to innovation and customer satisfaction.

Applications in Hydraulic Systems

Stauff’s brass fittings play a crucial role in various hydraulic systems. Engineers use these fittings for secure and leak-free connections in fluid circuits. They perform effectively in high-pressure applications. Stauff’s brass fittings are essential for mobile hydraulics, industrial machinery, and heavy equipment. Their robust construction handles vibrations and pressure fluctuations common in these systems. The fittings ensure efficient fluid transfer, maintaining system integrity and operational safety. Stauff stands among the leading Brass Fittings Manufacturers providing critical components for complex hydraulic applications worldwide. Their products contribute significantly to the reliability and performance of modern fluid power technology.

Midland Metal Mfg.: Comprehensive Brass Fittings Range

Company Overview and Product Diversity

Midland Metal Mfg. has established itself as a leading supplier in the fluid power industry. The company offers a vast selection of products. They are recognized among prominent Brass Fittings Manufacturers. Midland Metal Mfg. provides a comprehensive range of brass fittings. This extensive catalog ensures solutions for diverse industrial requirements. Their product diversity covers numerous categories, including:

- Pipe Fittings

- Hose Barb Fittings

- Push-On Barb Fittings

- Garden Hose Fittings

- 45° Flare Fittings

- JIC 37° Flare

- Inverted Flare Fittings

- Compression Fittings

- Flareless Fittings

- Push-In Fittings

- DOT Push In

- Air Brake Fittings

- Grease Fittings

- Specialty Valves and Cocks

This broad offering highlights Midland Metal Mfg.’s commitment to meeting varied customer needs. They supply components for many different connection types and applications.

Industrial and OEM Applications

Midland Metal Mfg.’s brass fittings find widespread use across various industrial and OEM (Original Equipment Manufacturer) applications. Industries rely on these fittings for their durability and reliable performance. Manufacturers integrate them into hydraulic and pneumatic systems. They also appear in lubrication lines and general fluid transfer setups. The robust construction of Midland Metal Mfg.’s brass fittings ensures secure connections. This prevents leaks and maintains system integrity. OEM clients value the company’s ability to provide a consistent supply of high-quality components. These fittings support the assembly of new machinery and equipment. Their versatility makes them suitable for custom solutions. This adaptability helps meet specific design requirements in diverse manufacturing environments.

Curtiss-Wright (Farris Engineering): Engineered Brass Fittings

Company Integration and Product Focus

Curtiss-Wright operates as a global diversified company. It provides highly engineered products and services. Farris Engineering functions as a key business unit within Curtiss-Wright. Farris specializes in the design and manufacture of pressure relief valves. This strategic integration allows Curtiss-Wright to offer comprehensive safety solutions. Their product focus includes critical components for various industrial applications. They engineer these components for reliability and performance. This ensures systems operate safely under extreme conditions. The company leverages extensive engineering expertise to develop these specialized fittings.

Specialized Industrial Solutions

Farris Engineering, under Curtiss-Wright, provides specialized brass fittings. These fittings are integral to their pressure relief valve systems. They design these valves for demanding industrial environments. These components ensure the safe operation of complex machinery. For example, Farris offers specific series of ASME NB Certified Pressure Relief Valves. These valves feature brass components.

- SERIES 1896M ASME NB Certified Pressure Relief Valve: This valve includes a brass body and trim. It also features a bronze bonnet. It is suitable for air, steam, gas, and water applications. Industries use it in power generation and chemical processing.

- SERIES 2856 ASME NB Certified Pressure Relief Valve: This series also uses a brass body and trim. It has a bronze bonnet. This valve is designed for air, steam, and gas applications. It provides essential protection in oil and gas facilities.

These engineered brass fittings ensure safety and operational integrity. They protect critical systems from overpressure conditions. Curtiss-Wright (Farris Engineering) stands out among Brass Fittings Manufacturers for its focus on safety-critical applications. They deliver robust and reliable solutions to industries worldwide. Their expertise in pressure management makes their brass components vital for industrial safety.

Selecting High-Quality Brass Fittings Manufacturers

Product Range and Customization Capabilities

When selecting a manufacturer, consider their product range and customization options. Leading Brass Fittings Manufacturers offer a comprehensive selection. This includes specific angles, sizes, and threading. Manufacturers like Production Materials, Inc. provide various finishing options. These include galvanized, polished, painted, black oxide, and cadmium zinc. H & R Screw Machine Products, Inc. offers customized building plumbing services. They also provide product layout options, plate finishing, anodizing, and heat treating. A broad product line ensures buyers find the right fitting for any industrial application. Customization capabilities allow for unique project requirements.

Adherence to Quality Standards and Certifications

High-quality brass fittings meet strict industry standards. Manufacturers must adhere to material standards. These define acceptable brass alloys. Design and manufacturing standards establish performance criteria and operational limits. Quality assurance processes and testing procedures verify compliance. Regulatory requirements ensure safety, especially for drinking water systems. Certification marks provide visible confirmation of adherence. Examples include NSF/ANSI 61 and ASTM F877 for brass PEX fittings. Third-party testing offers additional assurance of quality and reliability.

Material Composition and Durability Factors

Brass is an alloy primarily composed of copper and zinc. This composition contributes to its corrosion resistance. It helps maintain integrity over time. This reduces the need for frequent replacements in industrial settings. Copper provides excellent thermal and electrical conductivity. Zinc enhances strength and corrosion resistance. Different brass alloys, such as red brass or yellow brass, achieve specific characteristics. These include improved machinability, increased corrosion resistance, and greater strength under stress. These compositions allow brass fittings to withstand demanding conditions. This includes high pressure, high temperature, moisture, chemicals, and salts.

Manufacturing Processes and Precision Engineering

Precision engineering ensures the reliability of brass fittings. Precision machining is a key process. It uses standard turning capacity for various brass alloys. These include free machining brass, red brass, lead-free brass, and dezincification resistant brass. Statistical Process Control (SPC) integrates into high-volume production. This prevents manufacturing problems and drives process improvement. CNC machining achieves high accuracy. Turning is efficient for bushings and threaded parts. Milling handles complex geometries. Drilling and tapping ensure hole and thread integrity. Finishing operations like deburring eliminate sharp edges. Honing and grinding achieve smooth surfaces for leak-free performance.

Customer Feedback and Technical Support

Customer feedback offers valuable insights into a manufacturer’s reliability. Positive reviews indicate consistent product quality and service. Strong technical support is also crucial. Manufacturers should provide expert assistance for product selection and troubleshooting. This ensures proper application and optimal performance of the fittings. Responsive support helps resolve issues quickly. It minimizes downtime in industrial operations.

Global Reach and Supply Chain Reliability

A manufacturer’s global reach and supply chain reliability are important. Look for ISO 9001 for quality management. RoHS compliance for hazardous substance restrictions is also important. Assess manufacturing capabilities. This includes advanced machinery, production capacity, and customization abilities. Evaluate shipping experience to your region. Appropriate packaging and clear lead times are essential. Prioritize suppliers who respond promptly. They should provide detailed information and excellent support.

Selecting the right Brass Fittings Manufacturers is crucial. Quality and innovation play critical roles in this decision. Procurement professionals and engineers must make informed choices. This ensures optimal performance and reliability in industrial applications. They should carefully consider all factors discussed to achieve success.

FAQ

What makes brass fittings suitable for industrial use?

Brass fittings offer excellent corrosion resistance, durability, and malleability. They withstand high temperatures and pressures, ensuring reliable connections in demanding industrial environments.

How do manufacturers ensure the quality of brass fittings?

Manufacturers adhere to strict material and design standards. They implement rigorous quality assurance processes, including testing and certifications like ISO 9001, to guarantee product performance and reliability.

What are common applications for brass fittings?

Brass fittings find extensive use in hydraulic, pneumatic, and instrumentation systems. They are crucial for fluid transfer in automotive, construction, oil and gas, and general industrial machinery.

Post time: Oct-18-2025