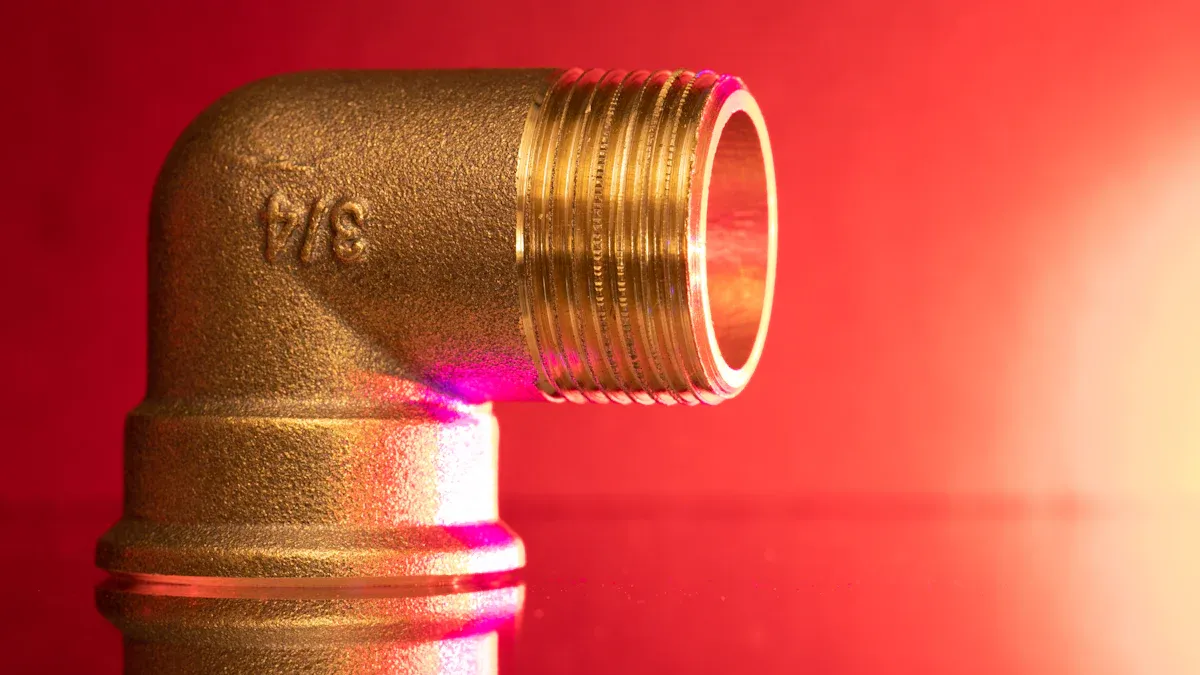

Nordic-approved brass tee fittings deliver unmatched reliability in extreme heating systems. These components withstand rapid temperature changes without failure. Engineers trust their proven durability for critical operations. By selecting brass tee fittings, system designers ensure both safety and long-term performance, even during the harshest thermal fluctuations.

Key Takeaways

- Nordic-approved brass tee fittings resist rapid temperature changes, preventing cracks and leaks in extreme heating systems.

- Brass offers strong heat resistance, corrosion protection, and stable performance, making it ideal for harsh thermal conditions.

- Choosing certified brass fittings and following proper installation and maintenance ensures long-lasting, safe, and reliable heating systems.

Brass Tee Fittings and Thermal Shock Resistance

What is Thermal Shock in Heating Systems

Thermal shock describes a sudden and significant change in temperature that creates intense stress within a material. In heating systems, this phenomenon occurs when components experience abrupt shifts in heat flux and temperature gradients. These rapid changes force materials to expand or contract unevenly, generating internal stresses that can exceed the material’s strength. When this happens, cracks or even catastrophic failures may result. For example, when cold water enters a hot boiler, the temperature difference causes the metal to expand and contract quickly. This process leads to stress cycling, which can shorten the lifespan of system components. Thermal shock is especially problematic in materials with low thermal conductivity and high thermal expansion coefficients, as these properties make them more susceptible to cracking and brittle fracture.

Note: Preventing thermal shock often involves controlling the rate of temperature change and selecting materials with robust thermal properties.

The Impact of Thermal Shock on Brass Tee Fittings

Heating systems in both commercial and residential settings face several common causes of thermal shock. Introducing cold water into a hot system without proper tempering stands out as a primary culprit. This action causes rapid expansion and contraction of internal components, including tee fittings, valves, and pipes. Over time, repeated cycles of heating and cooling can lead to metal fatigue, cracks, and eventual failure. Corrosion from water vapor inside heat exchangers further weakens materials, making them more prone to cracking. Poor installation practices, such as improper support or excessive vibration, can also contribute to fractures that may not appear immediately but develop over time.

Brass Tee Fittings that lack proper approval or are not designed for extreme conditions often fail in several ways:

- Material softening at high temperatures

- Degradation of seals and O-rings, especially above 250°F (121°C)

- Loss of press-fit integrity due to thermal expansion

- Accelerated corrosion and warping

- Leaks at stressed joints

Regular inspection and maintenance remain essential to prevent catastrophic failures in systems exposed to frequent thermal cycling.

Why Brass Tee Fittings Excel in Extreme Conditions

Brass Tee Fittings offer several advantages that make them ideal for surviving thermal shock in demanding heating environments. Their favorable thermal conductivity allows efficient heat dissipation, which helps maintain stable performance even during rapid temperature changes. The heat resistance of brass preserves its mechanical strength and structural integrity at elevated temperatures. A relatively low coefficient of thermal expansion ensures excellent dimensional stability, reducing the risk of leaks or misalignment as temperatures fluctuate.

Brass also exhibits notable corrosion resistance, especially at high temperatures, due to its copper content and the formation of a protective oxide layer. Specific brass alloys, particularly those with higher copper content and additional alloying elements, provide enhanced strength and resistance to thermal degradation. These properties ensure long-term reliability and durability, even under repeated thermal cycling.

When compared to plastic alternatives, brass fittings operate reliably across a much wider temperature range, from -40°C to 200°C. Plastic fittings, by contrast, often fail at temperatures above 60°C and show a high failure rate in steam lines. Brass fittings also withstand significantly higher pressures, making them more durable under thermal stress. While stainless steel offers higher tensile strength and corrosion resistance in harsh environments, brass remains a preferred choice for indoor or mild settings where temperature fluctuations are common.

Tip: Proper installation, thermal insulation, and routine maintenance further enhance the performance and lifespan of brass tee fittings in extreme heating systems.

Nordic Approval and Key Performance Features

What Does ‘Nordic-Approved’ Mean for Brass Tee Fittings

Nordic approval represents a rigorous certification process for plumbing and heating components. Regulatory bodies in Nordic countries, such as SINTEF in Norway and RISE in Sweden, set strict standards for product safety, reliability, and environmental impact. These organizations test fittings under extreme temperature and pressure conditions. Only products that meet or exceed these benchmarks receive the Nordic approval mark.

Manufacturers must submit detailed technical documentation and undergo third-party laboratory testing. Inspectors evaluate the chemical composition of the brass, the mechanical strength, and the resistance to corrosion. Nordic-approved products also comply with strict requirements for lead content and drinking water safety. This certification assures engineers and installers that the fittings will perform reliably in the harshest climates.

Note: Nordic approval is recognized across Europe as a mark of excellence for heating system components.

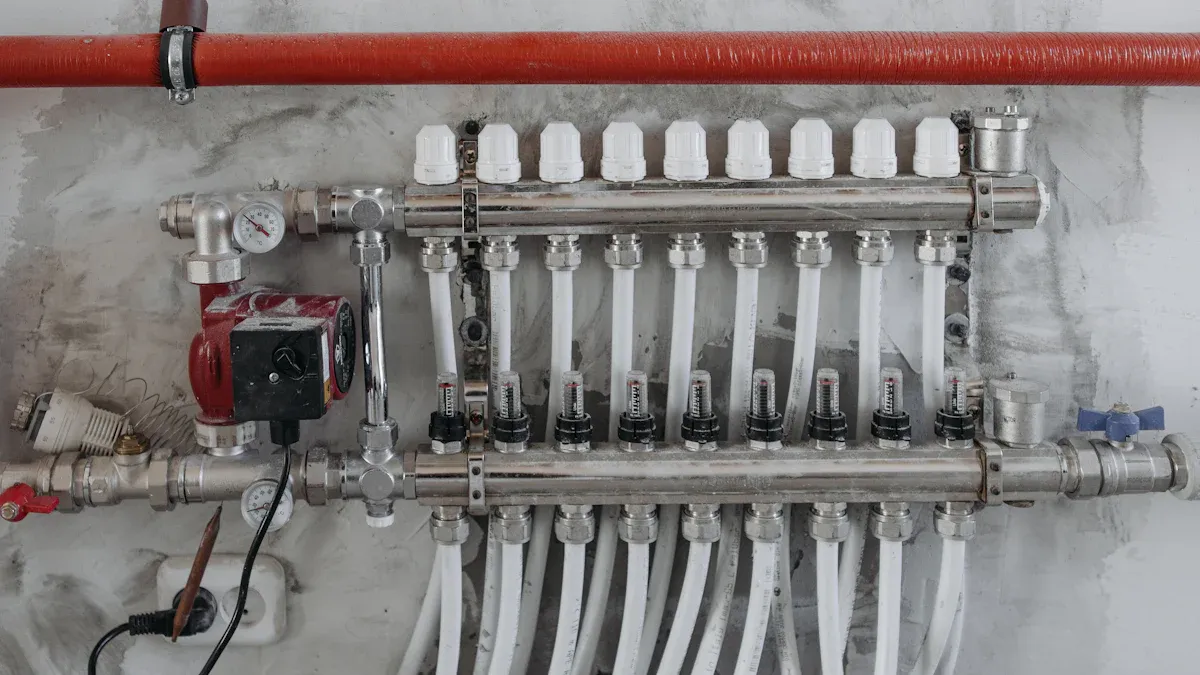

Design and Durability for Thermal Shock Survival

Engineers design Nordic-approved fittings to withstand rapid temperature changes and high mechanical stress. The geometry of each tee fitting ensures even distribution of thermal expansion forces. This design reduces the risk of stress concentrations that could lead to cracks or leaks.

Manufacturers select brass alloys with high copper content and minimal impurities. These alloys provide superior resistance to corrosion and thermal fatigue. The production process includes precision machining and advanced annealing techniques. These steps enhance the grain structure of the brass, increasing its toughness and flexibility.

A typical Nordic-approved tee fitting features:

- Thickened walls for added strength

- Reinforced joint areas to prevent deformation

- High-quality seals that maintain integrity at both low and high temperatures

- Surface treatments that resist scaling and oxidation

The combination of robust materials and thoughtful engineering ensures long service life, even in systems exposed to frequent thermal cycling.

Real-World Performance and Test Results

Independent laboratories conduct extensive testing on Nordic-approved fittings. These tests simulate years of operation in extreme environments. The process includes repeated cycles of rapid heating and cooling, exposure to aggressive water chemistries, and high-pressure bursts.

The following table summarizes key test parameters and typical results for Nordic-approved tee fittings:

| Test Type | Standard Requirement | Typical Result |

|---|---|---|

| Thermal Shock Cycling | 10,000 cycles | Pass (no cracks) |

| Pressure Resistance | 25 bar (363 psi) | Pass (no leaks) |

| Corrosion Resistance | 1,000 hours in salt fog | Pass (minimal change) |

| Dimensional Stability | ±0.2 mm after cycling | Pass |

Field reports from Nordic countries confirm these laboratory findings. Installers report fewer failures and reduced maintenance costs when using Nordic-approved components. Systems equipped with these fittings operate reliably through harsh winters and sudden temperature swings.

Post time: Jul-24-2025