Quick and Easy Fittings (PPSU Material) transform hygienic piping with superior safety and unmatched durability. These fittings deliver a service life of at least 50 years, resist corrosion, and comply with strict drinking water standards. Installation takes half the time compared to copper systems, reducing costs and labor demands.

Key Takeaways

- PPSU Quick and Easy Fittings offer superior safety and durability, lasting over 50 years without corrosion or harmful substance release, making them ideal for hygienic piping.

- These fittings install much faster than traditional metal systems, reducing labor time and costs with a simple, tool-free process anyone can perform.

- Choosing PPSU fittings lowers maintenance needs and overall expenses, providing long-term savings and helping professionals meet strict hygiene and safety standards.

Challenges in Hygienic Piping and the Shift to Quick and Easy Fittings (PPSU Material)

Limitations of Brass and Metal Fittings

Brass and metal fittings have long served in hygienic piping, but research highlights several critical drawbacks. Brass fittings, especially those containing lead, often fail due to corrosion and lead leaching. Even when certified, these fittings can release harmful substances into water, especially under high flow velocities or when installation leaves behind corrosive residues. Corrosion not only shortens the lifespan of metal fittings but also increases maintenance needs and the risk of bacterial growth. These issues have prompted regulatory bodies to tighten standards, pushing the industry to seek safer alternatives.

Traditional metal fittings, particularly those with lead, face increasing scrutiny as regulations like the EU Drinking Water Directive limit allowable lead content.

Rising Hygiene and Safety Demands

Growing awareness of waterborne diseases and contamination risks has driven demand for improved hygiene in piping systems. Studies show that even piped water does not always guarantee microbiological safety. Intermittent supply, poor storage, and loss of pipe pressure can allow contaminants to enter the system. Surveys reveal that many healthcare facilities, especially in low- and middle-income countries, lack adequate hygiene infrastructure. Regulatory action, leadership engagement, and dedicated resources have become essential for raising hygiene standards.

| Survey Year(s) | Framework | Key Findings |

|---|---|---|

| 2011-2019 | WHO HHSAF, Global WASH | Regulatory action and leadership drive higher hygiene standards; gaps persist in low-resource settings. |

The Search for Long-Lasting, Reliable Solutions

Professionals now prioritize solutions that offer durability, safety, and compliance. Persistent challenges include biofilm formation, corrosion from aggressive cleaning agents, and human error during maintenance. Market analysis shows strong growth in demand for reliable piping systems, especially those that resist chemical degradation and maintain integrity over decades. Quick and Easy Fittings (PPSU Material) address these needs with superior chemical resistance, biological inertness, and long-term performance, making them a preferred choice for modern hygienic piping.

Advantages of PPSU Quick and Easy Fittings (PPSU Material)

Mechanical and Chemical Strength

PPSU demonstrates exceptional mechanical and chemical strength, making it a preferred material for demanding piping applications. Researchers have found that PPSU outperforms other engineering plastics such as polysulfone and polyimide in both impact resistance and chemical stability. This strength results from its unique molecular structure, which incorporates tetramethylbiphenol moieties. These structural features increase the free volume and chain rigidity of the polymer, enhancing both gas transport properties and mechanical toughness.

- PPSU maintains high-temperature tolerance and dimensional stability, even under continuous mechanical stress.

- The material resists radiation sterilization, alkalis, and weak acids, which are common in hygienic environments.

- PPSU’s robust polymer matrix supports high permeability and sorption coefficients for gases like CO2, indicating superior chemical stability.

Manufacturers often select PPSU for medical instrument components and hot water fittings, where both mechanical durability and chemical resistance are essential. Quick and Easy Fittings (PPSU Material) leverage these properties to deliver reliable performance in environments that demand both strength and resilience.

Certified Safety and Regulatory Compliance

Safety and compliance remain top priorities in modern piping systems. PPSU fittings have achieved several key certifications, confirming their suitability for critical applications. The following table summarizes the main certifications and standards met by PPSU fittings:

| Certification / Standard | Details and Status |

|---|---|

| UL Listing (UL 1821) | Achieved for specific PPSU-PEX fitting combinations |

| FM Global | Approved for light hazard occupancies; full-scale fire tests pending |

| NFPA 13 | Requires special permission for non-metallic systems |

| European Standard EN 12845 | Permits use of PPSU fittings in pre-action sprinkler systems |

| DIN 14800 Testing | Passed in German automotive plant for ESFR system use |

These certifications demonstrate that PPSU fittings meet rigorous safety and performance requirements. Regulatory bodies in both the United States and Europe recognize the reliability of PPSU in fire protection and drinking water systems. Quick and Easy Fittings (PPSU Material) help professionals ensure compliance with evolving standards, reducing the risk of regulatory issues and supporting public health.

Corrosion Resistance and Extended Lifespan

Corrosion remains a major concern in traditional piping systems, often leading to leaks, contamination, and costly repairs. PPSU’s chemical structure provides outstanding resistance to corrosion, even when exposed to aggressive cleaning agents or fluctuating water quality. Laboratory tests confirm that PPSU fittings maintain their surface chemistry and mechanical properties over extended periods.

| Test/Measurement | Description | Key Findings Supporting Durability of PPSU Fittings |

|---|---|---|

| XPS Elemental Composition (Carbon & Oxygen) | Measured over 212 days and extrapolated to 417 days under ambient air and darkness | Carbon and oxygen content changed by only ~1 atom% from 212 to 417 days, indicating minimal surface chemistry changes over time |

| Carbon Functionality Distribution (C=O, (C=O)–O, C–S, C–C) | Analyzed under various plasma treatment conditions | Oxidation products formed and stabilized; harsh plasma conditions required for chain scission; surface oxidation remains stable with only slight changes over time |

| Wettability (Contact Angle) | Contact angles measured for plasma treated and untreated samples | Plasma treated PPSU shows high wettability (droplets absorbed quickly), indicating stable surface modification; hydrophobic reference sample had contact angle ~130° |

| Time Extrapolation of Surface Properties | Carbon and oxygen content fitted to diffusion model and extrapolated to 10,000 hours (417 days) | Surface properties diminish logarithmically but would take hundreds of thousands of years to fully revert, demonstrating practical durability over expected lifetime |

These results show that PPSU fittings resist both chemical and physical degradation, ensuring a long service life. The material’s stability under oxidative and environmental stress means that Quick and Easy Fittings (PPSU Material) can deliver reliable performance for decades, even in challenging conditions.

PPSU vs. Traditional Materials

PPSU offers several advantages over traditional materials such as brass and copper. While metal fittings often suffer from corrosion, lead leaching, and biofilm formation, PPSU remains inert and stable. The following points highlight the key differences:

- PPSU does not corrode or release harmful substances into water, supporting higher hygiene standards.

- The material withstands repeated sterilization and exposure to cleaning agents, unlike metals that may degrade or pit over time.

- PPSU fittings maintain their mechanical integrity and surface properties for decades, reducing the need for frequent replacements.

Professionals who choose PPSU benefit from a piping system that meets modern safety, durability, and hygiene requirements. Quick and Easy Fittings (PPSU Material) set a new standard for reliability, helping facilities future-proof their infrastructure.

Installation and Cost Benefits of Quick and Easy Fittings (PPSU Material)

Streamlined Installation Process

Installers benefit from a much faster workflow when using Quick and Easy Fittings (PPSU Material). These fittings require no soldering, threading, or heavy tools. The assembly process is tool-free and intuitive, allowing even less experienced workers to achieve reliable connections. For example, a 10-meter pipe run can be completed in just 30 minutes with PPSU fittings, while copper piping takes about an hour. The following table highlights installation time comparisons:

| Material Type | Installation Time Compared to Steel |

|---|---|

| PPSU PEX | 60% faster |

| CPVC | 30% faster |

| Steel | Baseline |

This efficiency reduces project timelines and minimizes disruptions in both new builds and renovations.

Lower Labor and Maintenance Costs

PPSU systems deliver significant savings over their lifecycle.

- The lifecycle cost of PPSU PEX fittings is $8.20 per foot, much lower than steel at $12.50 per foot.

- Field data shows a 40% reduction in maintenance incidents compared to galvanized steel.

- Installation time is 60% faster than steel, which lowers labor costs.

- PPSU fittings resist corrosion, so maintenance related to leaks or scale is rare.

- Homeowners save between $500 and $1,000 over 20 years due to fewer replacements and repairs.

These savings make PPSU systems a smart investment for both commercial and residential projects.

Practical Value for Professionals

Professionals choose PPSU fittings for their proven performance and versatility.

| Performance Aspect | Details & Metrics |

|---|---|

| Pressure Retention | 16 bar at 23°C, 10 bar at 80°C |

| Longevity | Over 20 years in hot water, 50+ years with proper installation |

| Leak Rates | <0.01×DN mm/min, meeting API 598 standards |

| Installation Efficiency | Tool-free assembly, 50% faster than copper |

| Compatibility | Works with PEX, CPVC, and metal pipes |

| Maintenance | No corrosion treatments needed, easy scale removal |

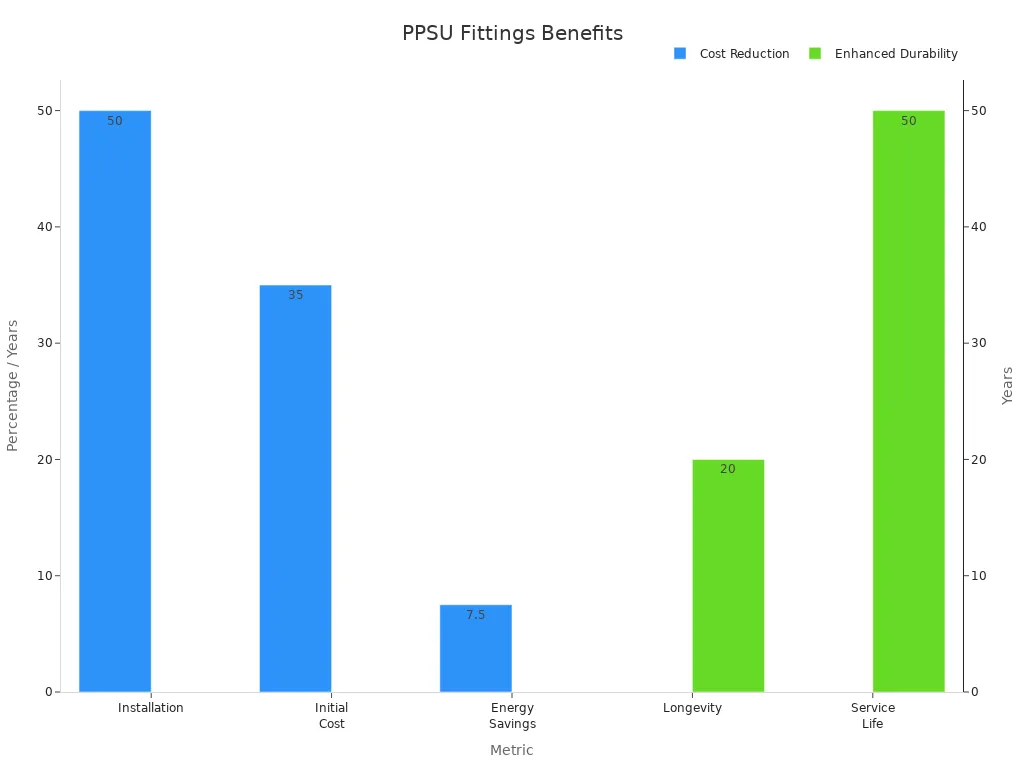

| Cost-Effectiveness | 30-40% lower initial cost than copper, energy savings of 5-10% |

Stephan Müller, a leading expert, notes that PPSU’s high impact strength, heat resistance, and compliance with strict EU standards make it ideal for potable water systems. Professionals gain a competitive edge by delivering safer, longer-lasting, and more cost-effective piping solutions.

Quick and Easy Fittings (PPSU Material) raise the bar for hygienic piping. They deliver unmatched safety, long-term durability, and simple installation. Many professionals now choose these fittings to meet strict standards. Forward-thinking teams rely on them to future-proof piping systems and ensure reliable performance.

FAQ

What makes PPSU fittings suitable for drinking water systems?

PPSU fittings resist corrosion and do not leach harmful substances. They meet strict international standards for potable water safety and hygiene.

Can professionals install PPSU quick and easy fittings without special tools?

Yes. Installers can connect PPSU fittings by hand. The process does not require soldering, threading, or heavy equipment.

How long do PPSU quick and easy fittings last in typical applications?

Most PPSU fittings deliver a service life of 50 years or more, even under demanding conditions. Regular inspections help ensure optimal performance.

Post time: Jun-26-2025