PEX press fittings have revolutionized plumbing by offering a seamless blend of reliability, convenience, and affordability. These fittings ensure robust connections that resist vibrations and eliminate the need for frequent maintenance. Their ease of installation stems from the flexibility of PEX pipes, which can navigate tight spaces effortlessly. With a projected market growth to USD 12.8 billion by 2032, their durability and cost-effectiveness are undeniable.

Key Takeaways

- PEX press fittings make strong and dependable connections. They stay tight and do not loosen over time.

- Installing them is fast and simple. This helps finish projects quicker without using fire or much prep work.

- These fittings save money and need no upkeep. They lower costs over time and help stop leaks.

Advantages of PEX Press Fittings

Reliable and Durable Connections

When it comes to plumbing systems, reliability is non-negotiable. PEX press fittings excel in creating strong, vibration-resistant connections. These fittings ensure that once a joint is pressed, it becomes a “dead connection,” eliminating the risk of accidental loosening over time. Their durability has been proven in high-pressure environments, with ratings between 80 and 125 psi. Some premium fittings can even withstand up to 160 psi, making them suitable for demanding applications. This level of reliability stems from the precision of the pressing tools and the robust design of the fittings, which include high-quality stainless steel sleeves.

Quick and Convenient Installation

Time is money, especially in construction and plumbing projects. PEX press fittings significantly reduce installation time compared to traditional methods like soldering or threading. The process involves sliding the pipe into the fitting and using a pressing tool to secure the connection. This can be completed in just a few minutes, allowing contractors to complete more jobs in less time. Unlike soldering, which requires open flames and extensive preparation, pressing is safer and cleaner. This convenience makes PEX press fittings a preferred choice for both professionals and DIY enthusiasts.

Cost-Effective and Maintenance-Free

PEX press fittings offer long-term economic benefits. Their maintenance-free nature eliminates the need for frequent repairs, reducing overall costs. Once installed, these fittings provide leak-free performance for years, minimizing water wastage and associated expenses. Additionally, the absence of on-site welding or threading reduces labor costs and the risk of installation errors. This combination of affordability and reliability makes PEX press fittings a smart investment for any plumbing system.

Versatility for Various Applications

One of the standout features of PEX press fittings is their versatility. They are compatible with both PEX and copper pipes, making them suitable for a wide range of applications. Whether it’s a residential water supply system, a commercial HVAC setup, or an industrial gas line, these fittings deliver consistent performance. They are also widely used in radiant heating systems, fire sprinkler installations, and even food processing facilities. Their ability to form secure, leak-proof seals without the need for clamps or adhesives further enhances their adaptability.

Suitable for Embedded Installations

In concealed plumbing systems, the risk of leaks can lead to costly repairs and structural damage. PEX press fittings are designed to meet the requirements of embedded installations, ensuring reliable performance in hidden environments. Their compact design and resistance to vibration make them ideal for tight spaces. Once installed, they require no maintenance, providing peace of mind for homeowners and contractors alike. This makes them particularly valuable in modern construction projects where aesthetics and functionality go hand in hand.

Precautions for Using PEX Press Fittings

Proper Use of Pressing Tools

Using pressing tools correctly is critical for ensuring the integrity of PEX press fittings. I always recommend gathering all necessary materials beforehand and verifying that they meet industry standards for safety and reliability. Before starting, I inspect the PEX pipes to ensure they are clean and smooth, as debris can compromise the connection. When using a PEX press tool, I follow the manufacturer’s instructions meticulously. Applying the correct amount of force is essential to maintain a secure connection without damaging the fitting. Additionally, wearing protective gear and adhering to installation codes ensures a safe working environment.

Selecting the Correct Fitting Sizes

Choosing the right fitting size is another crucial step. Incorrect sizes can lead to loose or overly tight connections, which may cause leaks or system failures. To simplify this process, I rely on measurement data to match the fitting size with the PEX pipe. Here’s a quick reference table for common PEX tubing sizes:

| PEX Tubing Size (CTS/Nominal) | Outside Diameter (OD) | Minimum Wall Thickness | Inside Diameter (ID) | Volume (gal/100ft) | Weight (lbs/100ft) |

|---|---|---|---|---|---|

| 3/8″ | 0.500″ | 0.070″ | 0.360″ | 0.50 | 4.50 |

| 1/2″ | 0.625″ | 0.070″ | 0.485″ | 0.92 | 5.80 |

| 5/8″ | 0.750″ | 0.083″ | 0.584″ | 1.34 | 8.38 |

| 3/4″ | 0.875″ | 0.097″ | 0.681″ | 1.83 | 11.00 |

| 1″ | 1.125″ | 0.125″ | 0.875″ | 3.03 | 17.06 |

This data helps me ensure the fittings and pipes are compatible, reducing the risk of installation errors.

Avoiding Over-Pressing or Under-Pressing

Over-pressing or under-pressing can compromise the connection’s integrity. Over-pressing may deform the fitting, while under-pressing can result in a weak seal. I always insert the PEX pipe fully into the fitting to the depth specified by the manufacturer. Then, I use the pressing tool to apply just the right amount of force. This ensures the connection is secure without damaging the pipe or fitting. Consistency in this process is key to achieving leak-free installations.

Inspecting for Leaks After Installation

Leak testing is a non-negotiable step in any PEX installation. After completing the connections, I use a pressure gauge to pump water into the system at the recommended levels. I monitor the pressure for several minutes, watching for any drops that might indicate a leak. During this time, I inspect all fittings and joints thoroughly. If I find any leaks, I address them immediately before closing walls or floors. This proactive approach prevents costly repairs down the line.

Protecting PEX from UV Exposure

PEX pipes are not designed to withstand prolonged exposure to ultraviolet (UV) radiation. Over time, UV rays can make the material brittle, increasing the risk of cracks and leaks. To mitigate this, I always recommend covering PEX pipes with UV-resistant materials or insulation. As one study highlights, “Prolonged exposure to UV radiation can cause the material to become brittle and more prone to cracking or leaking.” By taking this precaution, I ensure the longevity and reliability of the plumbing system.

PEX press fittings deliver unmatched reliability, ease of installation, and cost-effectiveness. Their ability to form secure connections without frequent maintenance makes them indispensable for modern plumbing systems. I always stress the importance of following precautions, such as proper tool usage and leak inspections, to ensure optimal performance.

The growing demand for PEX systems highlights their flexibility, strength, and resistance to corrosion. These qualities make them ideal for residential and commercial applications. I trust their high-quality brass casting, ISO-certified assurance, and diverse specifications to meet the needs of any project.

FAQ

What tools do I need to install PEX press fittings?

You’ll need a PEX press tool, pipe cutter, and measuring tape. These tools ensure precise connections and leak-free installations.

Can PEX press fittings be used for hot water systems?

Yes, PEX press fittings handle hot water systems effectively. Their durability and heat resistance make them ideal for residential and commercial applications.

How do I prevent leaks in concealed installations?

I recommend inspecting connections thoroughly and performing pressure tests. This ensures reliability before embedding fittings in walls or floors.

1. High quality brass casting

our products feature a one-piece forging construction that is pressure-resistant and explosion-proof, ensuring the safety of your operations.our brass casting products are not only convenient to install but also resistant to slipping and leakage, providing long-lasting and dependable performance.

2. ISO-certified quality assurance

Our products not only control quality assurance through ISO system, but also have advanced CNC machining and precision inspection equipment to ensure the highest level of quality and reliability. Our brass casting products have stable sealing performance and are ideal for a variety of applications, from pipelines and HVAC systems to industrial machinery and equipment.

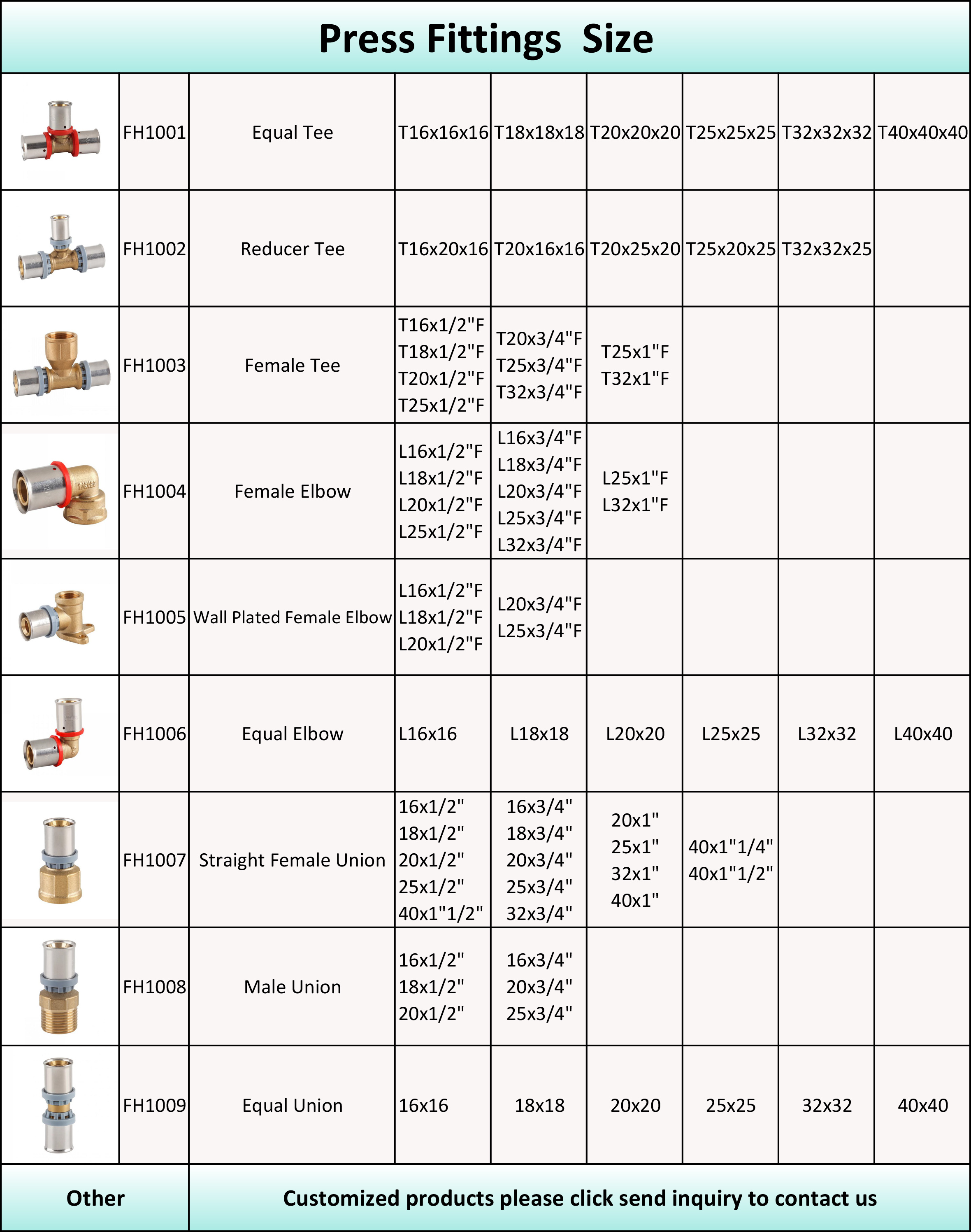

3. Multiple specifications available to suit your specific requirements

Whether you need a specific size or configuration, our products are available in multiple specifications to meet your exact needs.

Post time: May-30-2025